Digital Intelligence

At present, the company's digital intelligence department is continuously improving in the intelligent and unmanned cement manufacturing and digital production control by combining its own technological advantages. Through the construction of the Hongta Dianxi production control system, Guangxi Jinli unmanned cement grinding system, and Yunnan Fuyuan fully intelligent production line system, it has the ability to build intelligent cement production lines.

After 2021, digital models will be used as carriers to integrate data applications throughout the entire lifecycle, and technologies such as AI, IoT, and digital twins will be explored to gradually build a collaborative ecosystem of "BIM management+empowerment".

The current digital intelligence research work of the company has also achieved full process coverage, including digital design, digital procurement, digital logistics, smart construction, digital operation, and digital engineering technology research throughout the entire lifecycle of cement plants. Real time penetration and sharing of information at all stag.

Intelligent Factory Performance

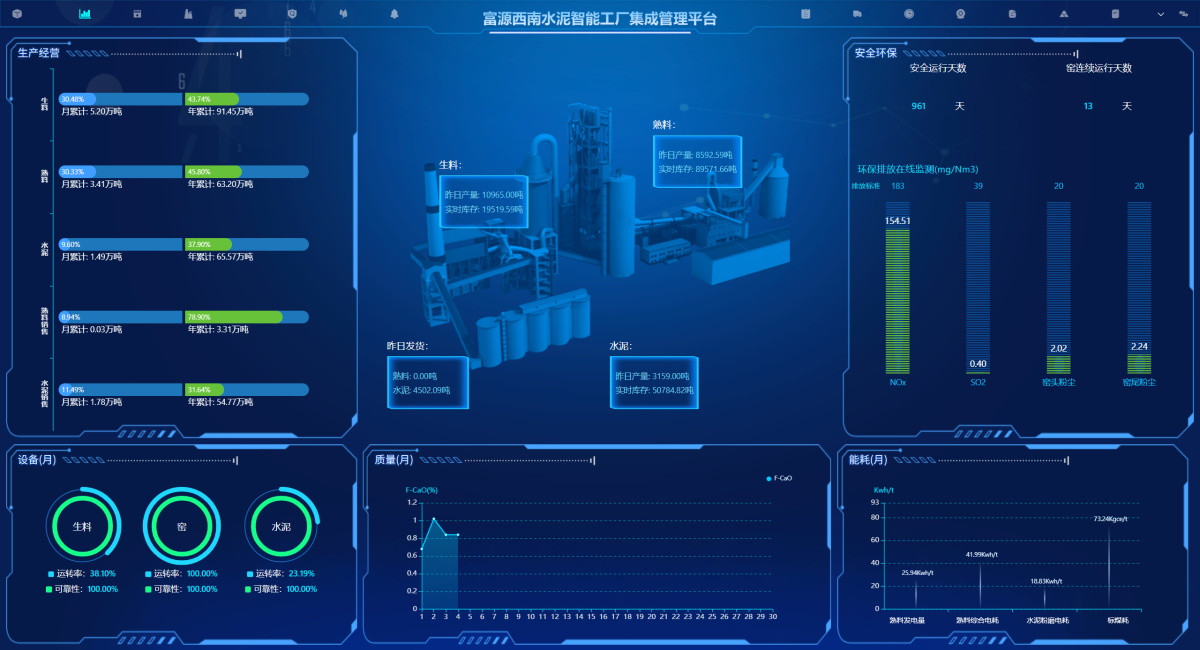

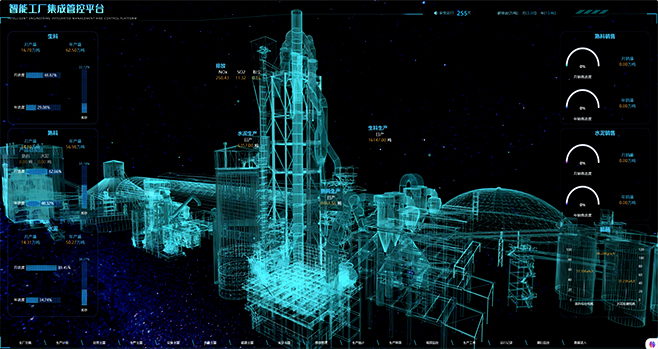

The construction of intelligent cement factories is an extension of digital design and construction. CDI leverage our design advantages and the execution advantages of EPC projects to create an integrated platform for intelligent cement factories. We use standardized interfaces, integration tools, and modular applications to meet the management needs of different users. One vertical and one horizontal (implementing role management from top to bottom and process management from left to right) achieve comprehensive management of the entire factory. It has been put into use in projects such as Hongta Dianxi, Egypt GOE Bunisuef, Fuyuan Southwest, and China Resources Wuxuan, covering the entire production and operation process control of production, energy, equipment, quality, safety and environment, logistics, etc., deeply mining the value of data, and continuously improving the application effect of lean production auxiliary decision analysis such as process power consumption analysis, material balance, and online thermal diagnosis. To achieve deep integration of logistics, information flow, business flow, and capital flow, and continuously empower lean production for enterprises.

BIM Performance

CDI have independently developed

BIM application management, digital intelligence empowerment, and business finance integration platforms, integrating core business modules to gradually achieve full process digital control.

Full life cycle management practice

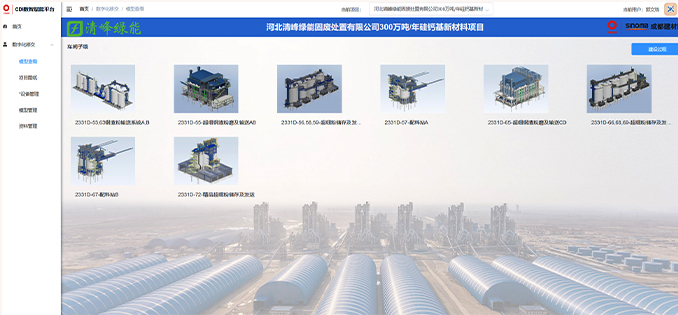

Taking the Qingfeng Green Energy Silicon Calcium Based Project as a pilot, extending BIM technology to the engineering management stage, exploring the practice of "design construction result delivery" BIM application management integrated digital platform.

International project technology breakthrough

Leading international projects such as the Saudi EPCC 10000 ton cement line and medical city, breaking through the barriers of multiple countries' standard differences, and successfully replicating technological achievements to three overseas projects.

Full process standardization application

covering the entire chain of bidding (3D visualization solution), detailed design (pipeline comprehensive optimization), construction (4D progress simulation), and management (BIM application management pla

Digital Intelligence Performance

Construction of a fully professional collaborative system: Innovatively establish a BIM fully professional collaborative design system, achieve full professional collaboration in benchmark projects such as Pingliang Qilian Mountain Aggregate, CR Wuxuan Cement Line, QCC Grinding Station, etc., reduce 80% of design conflicts through collision detection, optimize construction plans, and shorten construction periods.