Sccessful Application of Ultra-low NOx Emission Technology

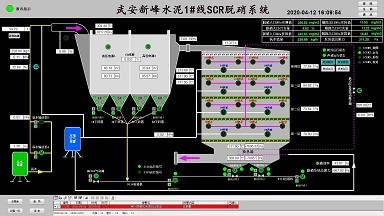

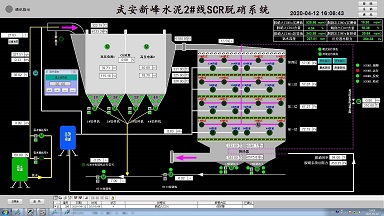

This upgrading project has adopted the three-stage composite denitration technology composed of “staged combustion in calciner + SNCR + SCR”, among which the SCR denitration technology, specifically targeting the exhaust gas of cement production line with high dust and high harmful ingredients, has effectively remedied, by using the process technology of “high temperature and medium dust content”, such technical problems of the cement production line as short lifetime of denitration catalyst and lower denitration efficiency after a long-period running. The actual operation figures have shown that the operation resistance of the whole SCR system is less than 800Pa and the temperature of the exhaust gas drops less than 10°C.

The fact of 6-month continuous stable running of the 3 sets of SCR denitration system of Wu’an Xinfeng Cement Company has demonstrated the maturity of CDI’s ultra-low NOx emission technology with “staged combustion in calciner + SNCR + SCR” as its core, and such technology will definitely have a broad prospect.